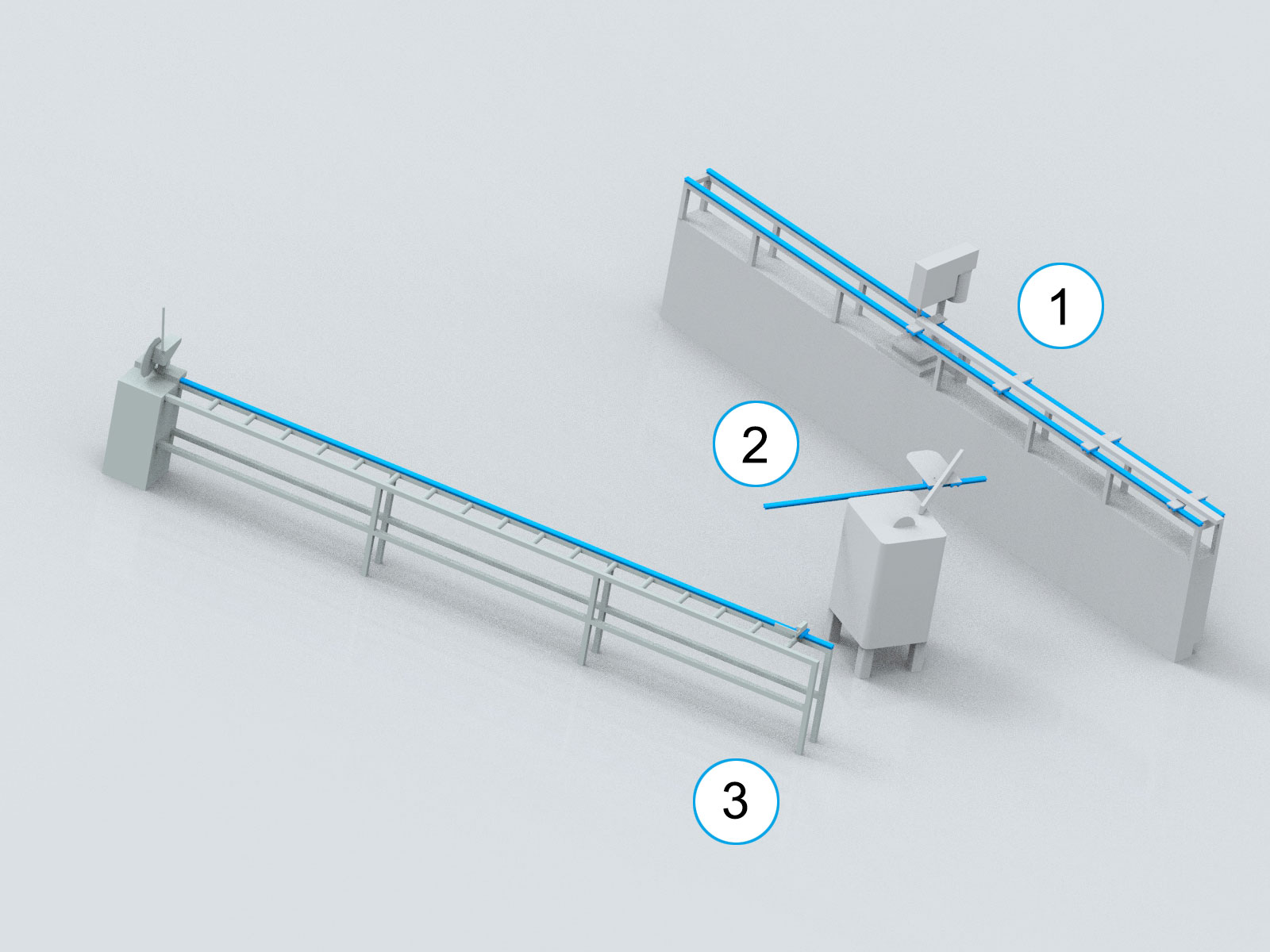

Machines and systems in industrial production must be designed to function reliably for as long as possible, often under extremely harsh environmental conditions. In the production process, the rails can often collect shavings, liquids, dust, or other substances.

Track roller guides are predestined for pick and place applications which feature dynamic processes and have long travel distances. In a wide variety of systems, these components are tailored to the motion sequences and ensure an uninterrupted, dynamic flow of materials. In addition to very fast workflows, the reliability of each system is equally important. As smooth processes lead to direct savings through increased plant productivity and a reduction in maintenance costs.

Advantages for machine operators:

- Avoiding situations that could lead to machine downtime

- Faster production runs

- Very dynamic flow of materials

- Drilling devices

- Circular saws

- Measuring stops