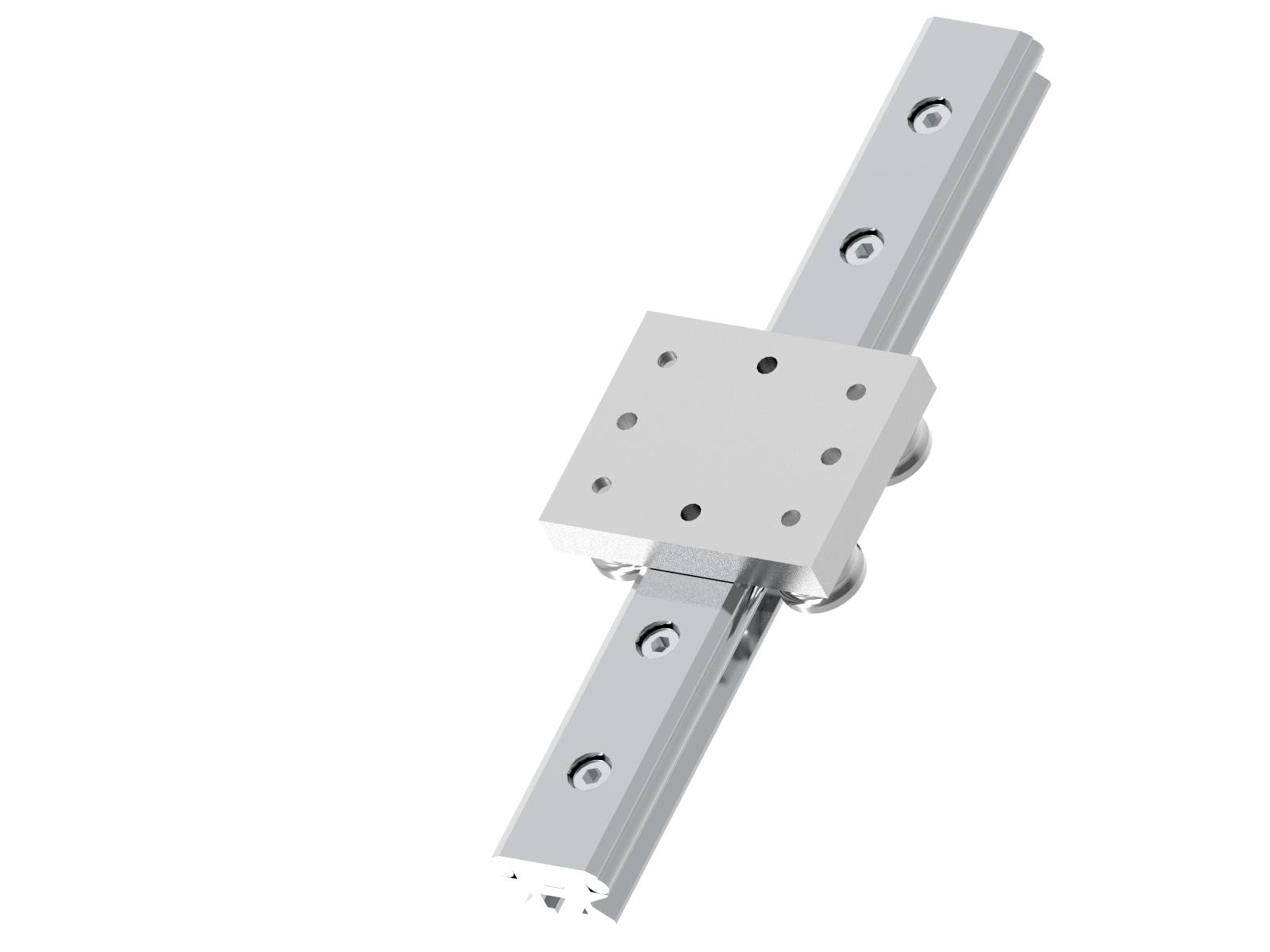

Track roller guidance systems

HUETHERTECH track roller guidance systems are built for linear motion applications and are characterized by their durability and silent operation with little need for maintenance.

These properties make these linear guidance systems indispensable components in mechanical engineering and fixture construction.

The linear guides form the heart of highly developed machines, but also in simple devices or equipment and are used across all industries.

Track roller guidance systems are easy to assemble, require little need for maintenance, and can be put into operation very quickly. Given their modular design, track roller guidance systems are also suitable for applications with very long travel distance.

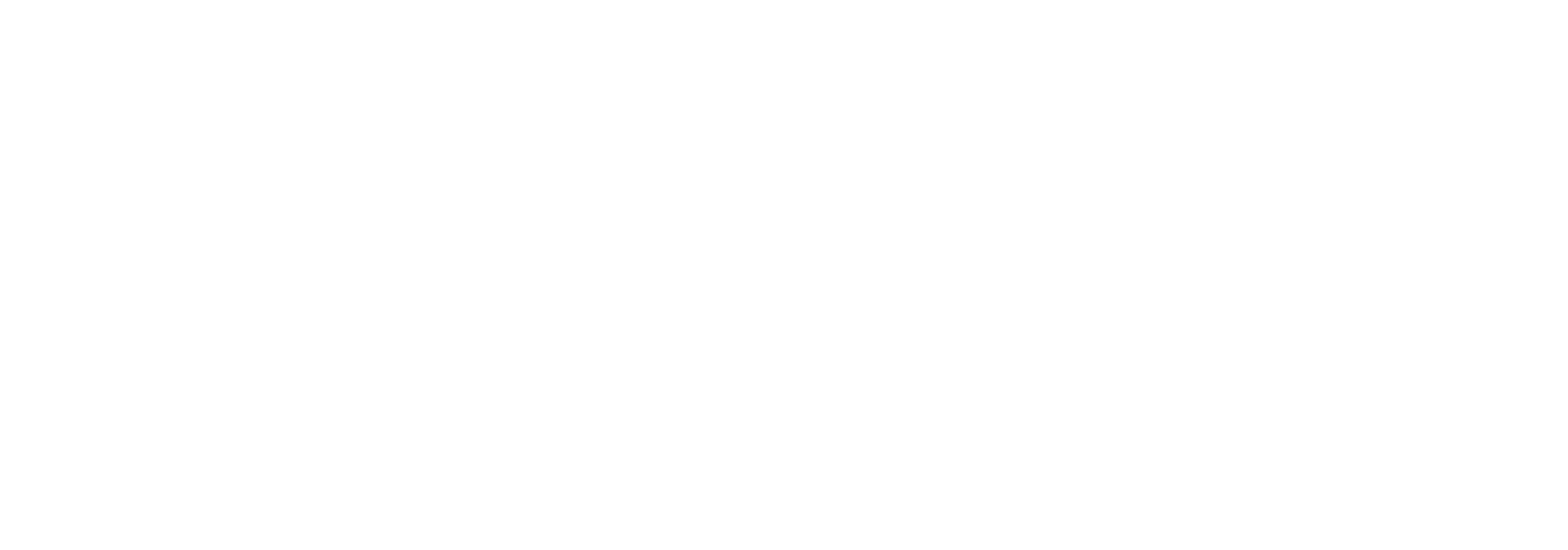

The system components include the support rails and the carriages.

The linear guide is delivered ready to screw on. The customer has the option of attaching the guide rail from above or below.

Vertical and horizontal movements are possible even in dirty and rough environments. Safe operation and a long service life are guaranteed with only low maintenance.

Range of application: The track roller guidance systems can be used at speeds of up to 10 m/s.

Installation

Position the support rail and fasten it hand-tight. Align the support rail. If necessary, press it against a stop edge and screw it tightly into place. Apply the correct tightening torque according to the table. Bring the carriage into position. Adjust the clearance to the guide rail using the eccentric bolt: Tighten clockwise. The track roller must be set against the raceway.

Lubrication

The rolling rack between the support rail and the track roller must be lubricated to avoid damage caused by tribocorrosion.

The required lubrication intervals for the support rail raceways depend on the surrounding conditions. The cleaner the surroundings, the less lubricant is needed. The correct interval and precise amount of lubricant can only be determined under operating conditions, since not all conditions can be calculated in advance.

The system must be lubricated at the latest whenever tribocorrosion occurs. This can be recognized by a reddish discoloration of the mating track or the outer ring. Afterwards, the lubrication intervals must be reduced.

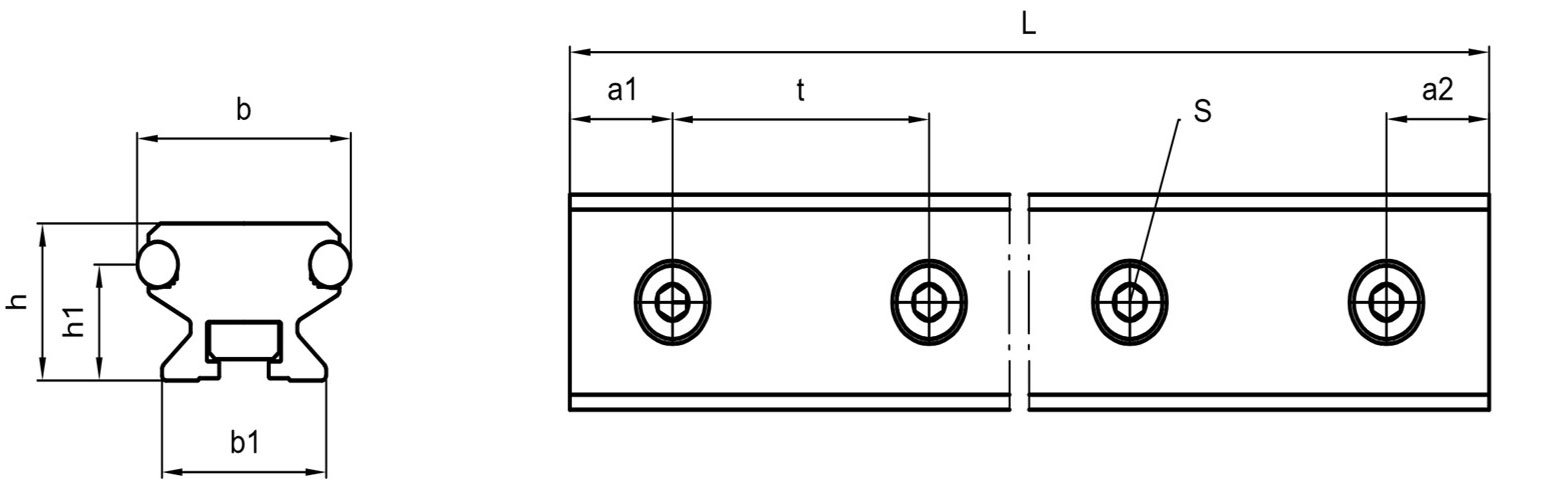

Support

The HLFS support rails is designed in a composite construction. Two polished precision steel shafts are fixed in an aluminum base element.

Track Rollers

The track roller is designed with a double-row angular ball bearing. The reinforced outer ring on the track rollers can withstand axial and radial forces. The track has a gothic profile and thus two points of contact with the shaft.

| Type | ||

|---|---|---|

| HLF32 | LFR50/8-6-2Z | LFZ8 LFE8-1 |

| HLF52 | LFR5201-10-2Z | LFZ12 LFE12-1 |

| HLF52E | LFR5301-10-2Z | LFZ12/M12 LFE12/M12-1 |

| HLF52EE | LFR5302-10-2Z | LFZ15 LFE15-1 |